SMG Rapid-Edge 100U Bottom Milling Type Plate Beveling Machine

The SMG Rapid-Edge 100M Top Milling Type Plate Beveling Machine is a high-performance, self- propelled plate edge milling machine, purpose-built for industrial-grade beveling. Designed for cold cutting using indexable inserts, it delivers precise, clean bevels without thermal distortion or pollution. Surface finish precision reaches Ra3.2 to Ra6.3, making it ideal for applications requiring high accuracy and a clean cut.

SMG Rapid-Edge 100U Bottom Milling Type Plate Beveling Machine

SMG Rapid-Edge 100U Bottom Milling Type Plate Beveling Machine

Frequently Asked Questions

What type of warranty and after-sales support do you provide with these machines or products ?

- Spare Parts Availability: We keep a wide range of commonly used spare parts and consumables in stock.

- Pre-Dispatch Checks: All machinery is thoroughly checked and pre-commissioned before leaving our facility.

- Support Options in the Event of a Fault:

- Remote Support: Assistance via email, phone, or live video to help diagnose and resolve issues.

- On-Site Service: Repairs carried out by our in-house service engineers or trusted repair contractors.

- In-House Repairs: Machines can be returned to us for expert inspection and servicing.

Description

SMG Rapid-Edge 100U Milling Type Plate Beveling Machine is a high-performance, self- propelled plate edge milling machine, purpose-built for industrial-grade beveling. Designed for cold cutting using indexable inserts, it delivers precise, clean bevels without thermal distortion or pollution. Surface finish precision reaches Ra3.2 to Ra6.3, making it ideal for applications requiring high accuracy and a clean cut.

Engineered for ease of use, the machine travels smoothly along the edge of metal plates, ensuring consistent performance and minimizing operator effort.

Features

- Self-Propelled Operation – The machine travels smoothly along the plate edge for continuous beveling with minimal operator input.

- Fitted with Universal Wheels – Easy to maneuver and relocate when not in use, ensuring simple transport and storage.

- Cold Cutting Technology – Uses industry-standard milling heads and carbide inserts to achieve bevels without generating heat or oxide layers.

- High Precision Finish – Delivers consistently smooth bevel surfaces with a roughness of Ra 3.2–6.3.

- Wide Working Range – Adjustable clamping system accommodates varying plate thicknesses and bevel angles with ease.

- Safety-Focused Design – Gear reducer located at the rear for improved operator safety and better balance.

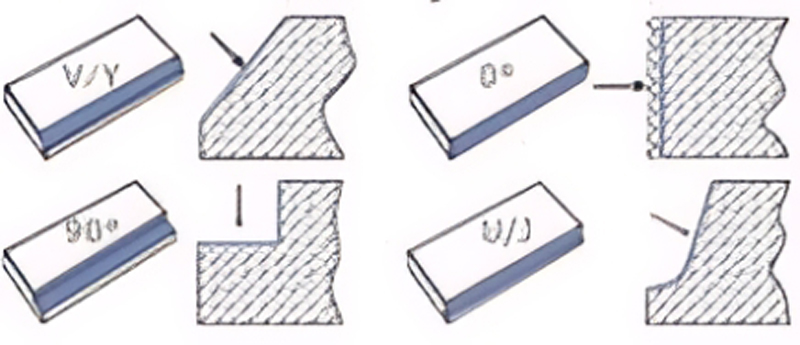

- Multi-Bevel Capability – Suitable for a range of bevel joint types including V, Y, K, X, U, J, L, and 0° clad removal.

- Adjustable Beveling Speed – Operates between 4–1.2 m/min, offering flexibility for different materials and requirements.

- Dual-Motor System – Delivers higher power and Adjustable cutter speed suits a variety of metal types.

- Top and Bottom Beveling Option – Use SMG Rapid-Edge 100M for top beveling and SMG Rapid-Edge 100U for bottom beveling – ideal for processing heavy-duty plates in tandem.

Bevel Joint Type

SMG Rapid-Edge-100M and 100U Milling Type Plate Beveling Machine in Action

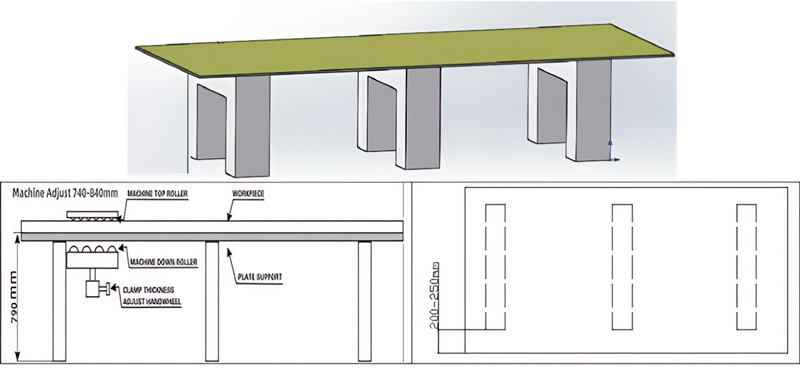

Working Table

Small Plate Applications:

For smaller workpieces, the machine remains mobile, moving along the edge of the plate. Material can be manually fed or used with an optional assist table to support continuous feeding.

Large Plate Applications:

For larger or heavy plates, it’s recommended to build a support table to hold the metal sheet securely in place. The machine will travel along the plate edge during operation.

Machine Packing List

| Model |

SMG-100U

|

| Power Supply | AC 415V 50Hz |

| Total Power | 6480W |

| Spindle Speed |

500-1050 mm/min

|

| Feed Speed | 0~1500 mm/min |

| Clamp Thickness | 6~100 mm |

| Clamp Width | >100 mm |

| Clamp Length | >300 mm |

| Bevel Angle | 0~ -45 degrees |

| Single Bevel Width | 15-30 mm |

| Bevel Width | 0~ 45 mm |

| Cutter Diameter | Dia 100 mm |

| Inserts QTY | 7 pcs |

| Worktable Height | 810-870 mm |

| Worktable Size |

1200 x 1200 mm

|

| Clamping Way | Auto Clamping |

| Machine Height Adjust | Hand wheel |

| Wooden Case Size |

1170 x 1200 x 1400 mm

|

| Machine Net Weight | 430 kg |

| Machine Gross Weight | 480 kg |