Cooper DryFlo DX400-AC – Diesel Rotary Screw Air Compressor with Aftercooler

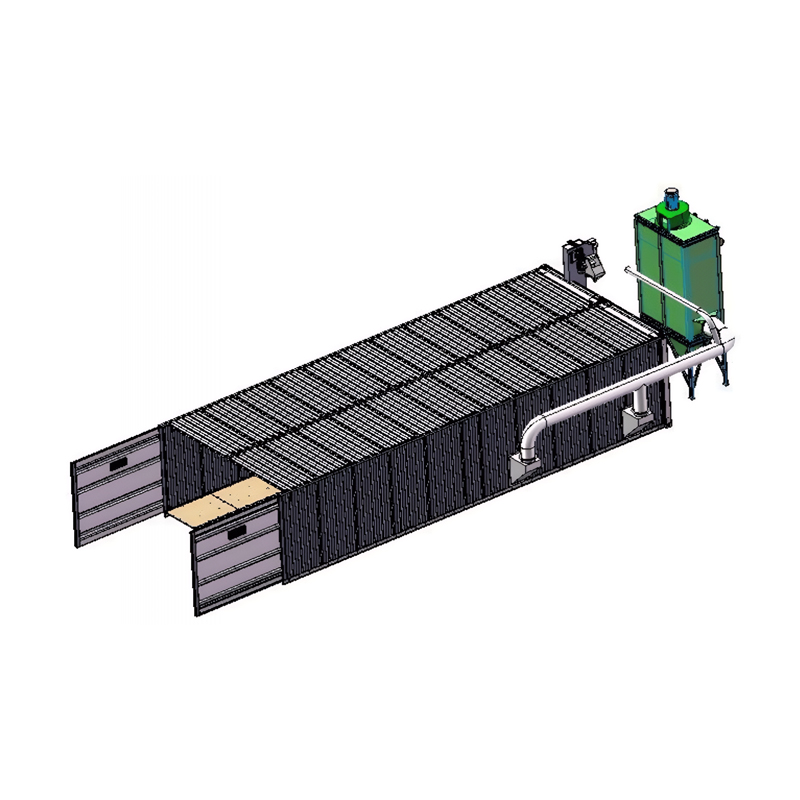

The Cooper DryFlo DX400-AC is a heavy-duty diesel rotary screw air compressor engineered for operators who need reliable, high-capacity air delivery in challenging environments. Built for durability and efficiency, it’s the ideal solution for construction, mining, manufacturing, equipment servicing, and abrasive blasting applications across Australia.

Powered by a Cummins QSB3.9-C150 Tier 3 diesel engine with 150 HP, this industrial diesel compressor delivers an impressive 406 CFM at 150 psi, providing continuous air supply for demanding operations. Its direct-driven, single-stage rotary screw system ensures consistent performance and reduced maintenance requirements, making it a dependable choice for both fixed and mobile setups.

Cooper DryFlo DX400-AC – Diesel Rotary Screw Air Compressor with Aftercooler

Cooper DryFlo DX400-AC – Diesel Rotary Screw Air Compressor with Aftercooler

Description

The Cooper DryFlo DX400-AC is a heavy-duty diesel rotary screw air compressor engineered for operators who need reliable, high-capacity air delivery in challenging environments. Built for durability and efficiency, it’s the ideal solution for construction, mining, manufacturing, equipment servicing, and abrasive blasting applications across Australia.

Powered by a Cummins QSB3.9-C150 Tier 3 diesel engine with 150 HP, this industrial diesel compressor delivers an impressive 406 CFM at 150 psi, providing continuous air supply for demanding operations. Its direct-driven, single-stage rotary screw system ensures consistent performance and reduced maintenance requirements, making it a dependable choice for both fixed and mobile setups.

Key Features

- High Air Output – 406 CFM (11.5 m³/min) at 150 psi for continuous heavy-duty performance

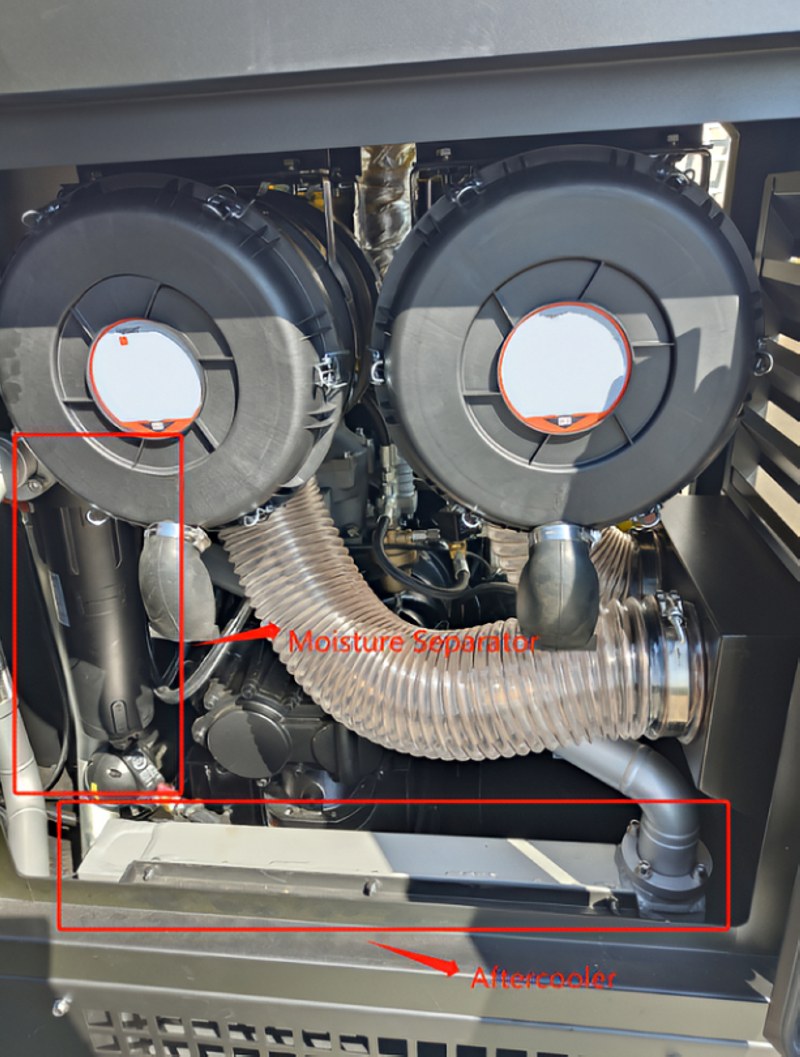

- Aftercooled System – Dry, clean air to protect equipment and improve process results

- Rugged Power – Cummins QSB3.9-C150 Tier 3 engine (150 HP)

- Versatile Configurations – Skid-mounted or trailer-mounted formats

- Smart Control – Digital interface with safety shutdown system and diagnostics

- Built for Australia – Withstands heat, dust, and remote conditions

- Low Maintenance Access – Simplified service points for fast upkeep

Why Dry Air Matters

The Cooper DryFlo DX400-AC’s aftercooled system with integrated water separator ensures your compressed air is dry, clean, and reliable — a critical advantage for industries where moisture can cause costly problems.

- Abrasive Blasting & Surface Prep – Prevents abrasive media clumping, maintains consistent blasting pressure, reduces flash rust, and keeps visibility clear inside blast chambers.

- Painting & Coating – Eliminates moisture that causes paint defects and poor powder coat adhesion, ensuring flawless finishes every time.

- Manufacturing & Production – Protects pneumatic tools and valves from corrosion, reduces wear, and maintains consistent air pressure for precision work.

- Food & Beverage Processing – Prevents bacterial growth and clogs in pneumatic conveyors, keeping packaging and ingredient transfer safe and efficient.

- Electronics & Semiconductor Manufacturing – Avoids condensation that can damage components, ensuring cleanroom compliance and product reliability.

- Pharmaceuticals & Medical – Protects product purity in capsule filling, tablet coating, and cleanroom operations, meeting GMP standards.

- Pneumatic Tools & Equipment – Extends tool life, maintains efficiency, and avoids costly downtime.

- Energy, Mining & Oil/Gas – Stops ice blockages and corrosion in instrument air systems, even in harsh, remote environments.

Bottom line: Dry air means better quality, less downtime, and longer-lasting equipment — making the DX400-AC the smarter choice for high-performance industrial air.

Performance Comparison

| Feature / Spec | Cooper DryFlo DX400-AC | Typical Diesel Compressor |

| Free Air Delivery | 406 CFM @ 150 psi | 300–350 CFM @ 150 psi |

| Air Quality | Aftercooled, dry & moisture-free | Uncooled, contains moisture |

| Engine Power | Cummins Tier 3 – 150 HP | 120–140 HP (varied brands) |

| Durability | Heavy-duty enclosure, mine-spec option | Standard industrial housing |

| Noise Level | 76 ±5 dB(A) | 80–85 dB(A) |

| Maintenance Access | Easy-access service points | Limited access to key components |

| Applications Supported | Construction, mining, blasting, coatings, manufacturing | General construction & light industry |

Shipping & Installation

- Dimensions (box type): 2200 × 1000 × 1300 mm

- Weight (dry): 1,450–1,850 kg (varies by configuration)

- Packaging: 1 × oversized pallet

- Delivery: Nationwide freight available

- Installation: On-site setup available through certified partners

Warranty & Support

- Warranty: 12-month / 2,000-hour standard coverage

- Service Network: Nationwide coverage with mobile support

- Spare Parts: OEM parts and consumables in stock

- Maintenance Plans: Custom service schedules available

Frequently Asked Questions

What type of warranty and after-sales support do you provide with these machines or products ?

- Spare Parts Availability: We keep a wide range of commonly used spare parts and consumables in stock.

- Pre-Dispatch Checks: All machinery is thoroughly checked and pre-commissioned before leaving our facility.

- Support Options in the Event of a Fault:

- Remote Support: Assistance via email, phone, or live video to help diagnose and resolve issues.

- On-Site Service: Repairs carried out by our in-house service engineers or trusted repair contractors.

- In-House Repairs: Machines can be returned to us for expert inspection and servicing.