HACO ATPX3015 CNC Pressbrake 3m x 150T

- Brand: Kingsland

In stock

Equipped with a Cybelec 2D operator control the ATPX series machines are a combination of modern technology with high accuracy, high speed positioning, large daylight opening and cylinder stroke, hydraulic tool clamping and most important, superior reliability and repeatability

Click Here Please note: This is the fastest way to receive an answer.

Stock levels cannot be checked over the phone.

HACO ATPX3015 CNC Pressbrake 3m x 150T

HACO ATPX3015 CNC Pressbrake 3m x 150T

Description

Standard Equipment

- Cybelec -2D Graphic Control with 15” Touch Screen

- Fast X/R 2-axis backgauge, with 4 tilt-able fingers

- Y1/Y2 Hydraulic SYNCHRO axis with 0.01mm positioning accuracy.

- Fast Approach Speed 140mm/sec

- Hydraulic Top Tool clamping system for Rolleri Quick Click tooling.

- Hydraulic clamping for European style V-dies.

- CNC Crowning Table

- Laser Safe PCSS integrated light guard system (made in WA)

- Operation, programming, and maintenance manual.

- Foot pedal control

Cybelec DNC15 2D Graphical operator control

The Cybelec DNC 15 is a 2D Graphic operator control with 15″ Touch Screen, offering the operator a quicker and more efficient interaction with his machine.

It features intuitive and interactive programming with clear and visible field functions associated with colorcodes thanks to the exceptionally clear 15″Touch Screen.

Furthermore, the controldisplays the optimal bending sequences, the tools and the position of the sheet between the tools as well as collision detection according to criteria defined by the operator. Some more features:

- Complete programming of parts on a single page.

- Quick set-up of the machine thanks to direct access to set-up parameters by means of clearly and logically designed menus and to basic functions by means of 5 object-oriented keys.

- Rapid data input due to the Touch Screen and slightly inclined ergonomic keyboard with large keys.

- Main machine commands (push buttons, switches) ideally located under the keyboard.

- The numerical control comes with off-line 2D software to prepare the production programs and check the feasibility of the parts on a desktop computer.

- Higher productivity through easy and rapid modifications of existing products.

- Extensive machine parameters allow very fine machine tuning.

- Display of error and warning messages on the console screen.

- Windows XP for multitasking and file management.

- EC safety-cycle management.

- Windows networking through Ethernet (RJ45).

- Connection to external devices through USB port for software updating and data backup.

- Almost unlimited quantity of programs and very high number of sequences.

Technical Dimensions

| Max press power | 150 | Ton |

| Bending length | 3200 | mm |

| Distance between frames | 2600 | mm |

| Max stroke length | 300 | mm |

| Gap inside frames | 400 | mm |

| Daylight opening | 550 | mm |

| Fast approach speed | 140 | mm/sec |

| Fast return speed | 130 | mm/sec |

| Pressing speed | 10 | mm/sec |

| Motor | 20 | KW |

| Weight | 14000 | Kgs |

2-Axis high speed backgauge

A heavy duty 2-axis (X-R) backgauge system, servo driven, on high-precision ball-screws.

Standard delivered with 4 tilt-able fingers manually adjustable in the width direction.

Positioning speed on X-axis: 250mm/sec

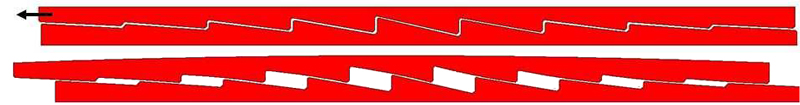

CNC crowning table (Anti-deflection)

A system of specific shaped wedges moving progressively over each other giving the table the desired form, resulting in constant angular profile of the work piece over the full working length. Having this system, allows very accurate bending, without having to re-set the European clamping wedges, to suit different lengths and thicknesses. The required theoretical calculated crowning is set by the CNC control.

Hydraulic top tool clamping for Rollery Quick Click tooling

This system offers a high degree of accuracy, tool changing speed and flexibility.

All top tools are hydraulically clamped and self-aligned, resulting in an optimal final bending accuracy.

Using the ROLLERI Quick Lock tooling, the top tools can vertically be exchanged quickly and safely.

Tools above 12Kg are to be removed horizontally for safety reasons.

Standard the machine is delivered with a TPR256-28-R1 top tool, 184mm high.

Rollerie Quick Click tooling is available in a wide range of different top tools, to adapt the machine to almost any specific job.

Hydraulic clamping for European style V-dies

All bottom dies are hydraulically clamped and self-aligned, resulting in an optimal final bending accuracy.

European style V-dies are available in a wide range of different sizes, to adapt the machine to almost any specific job.

European style V-dies are manufactured within the smallest tolerances in standard segmented lengths of 835mm and 415mm so they can be put together to achieve larger lengths.

Specification

Additional information

| Kilowatt (kW) |

|---|

Reviews

- press brake

- brake press

- sheet metal brake plans free download

- pressbrake

- brake machine

- sheet metal press

- press break

- press brake tooling

- brake machining

- break press

- press brake operator

- press breaker

- solidworks spring

- brake press tooling

- press brake machine

- cnc press brake

- hydraulic press brake

- press brake dies

- amada press brake

- used press brake

- used sheet metal equipment

- bending break

- cnc brake press

- brake press machine

- hydraulic brake press

- brake presses

- bending press

- press bending

- hydraulic brake animation

- brake form

- press brake tool

- cnc sheet bending machine

- cnc press brake jobs

- hydraulic press break

- hydraulic press brakes

- press brake tools

- table top hydraulic press

- brake press dies

- sheet metal brake press

- hydraulic metal brake

- used brake press

- hydraulic bending machine

- hydraulic die press

- cnc press

- brake dies

- used press brake dies

- hydraulic metal press

- mechanical press brake

- hydraulic press brake manufacturers

- used hydraulic press brake

- pneumatic bending machine