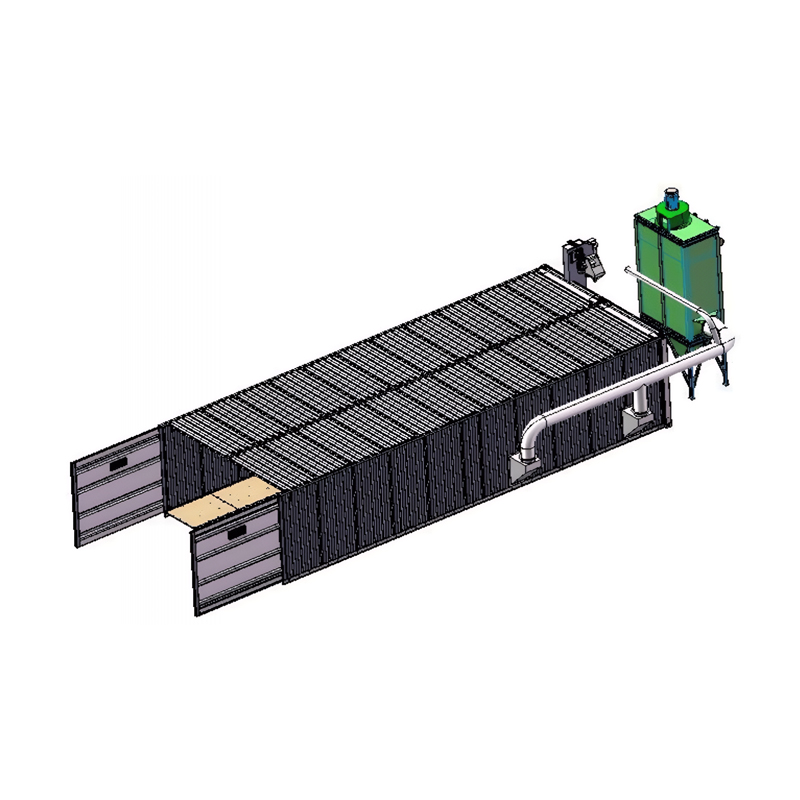

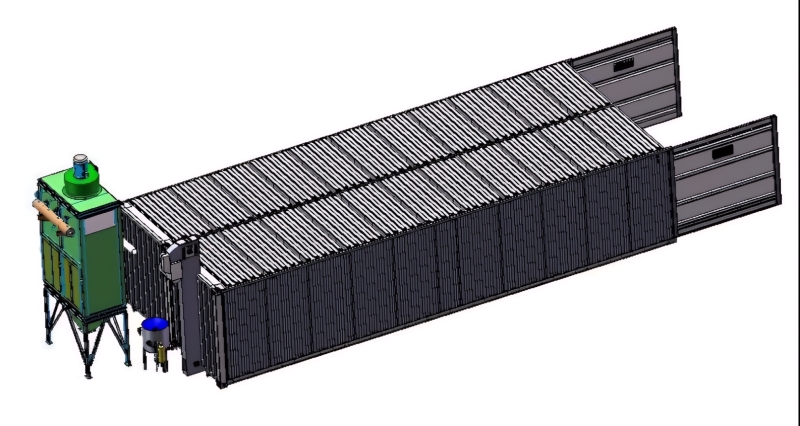

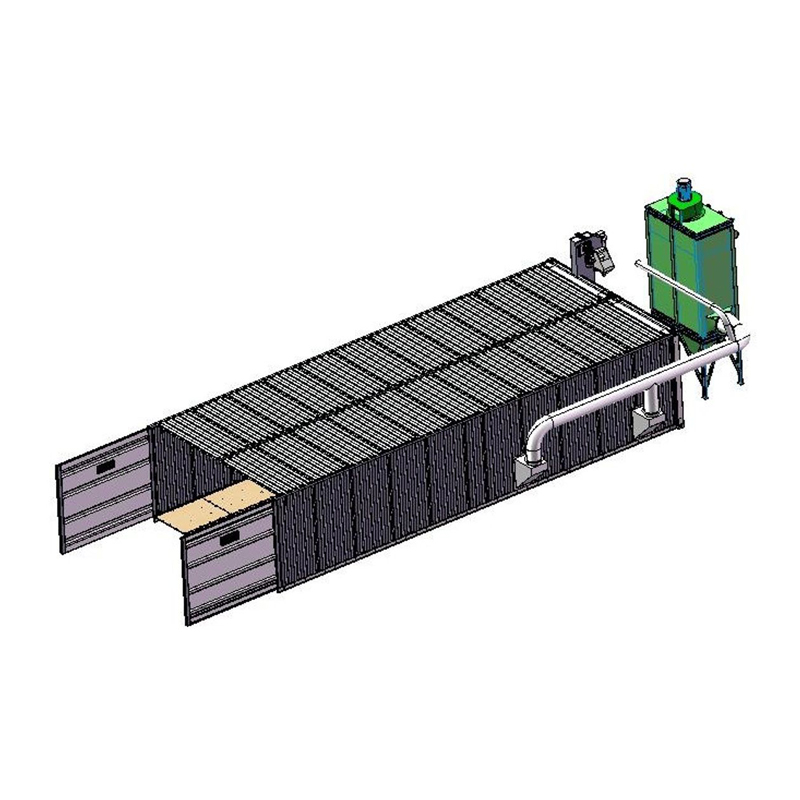

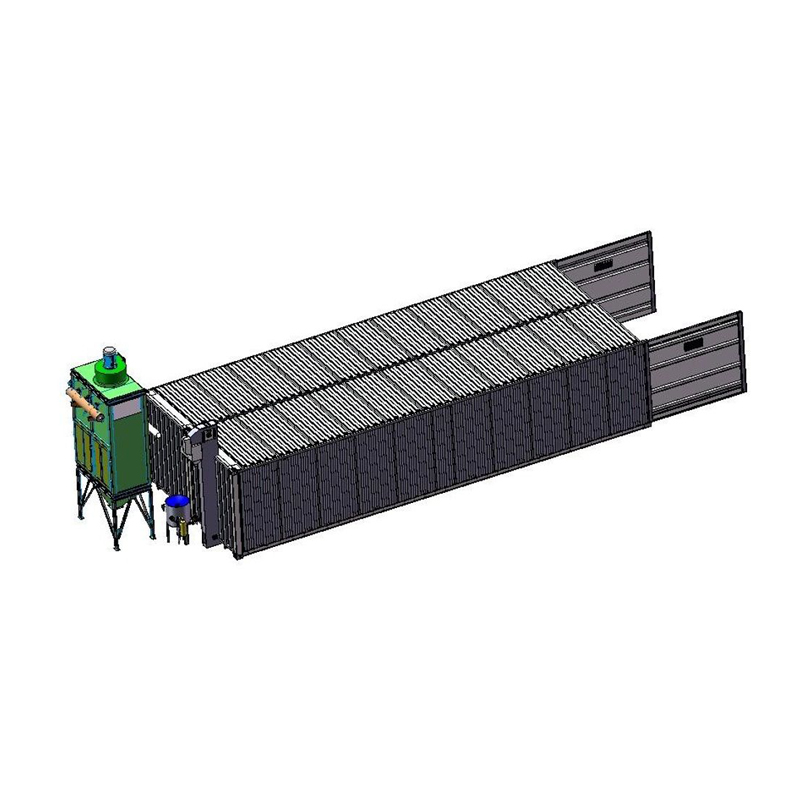

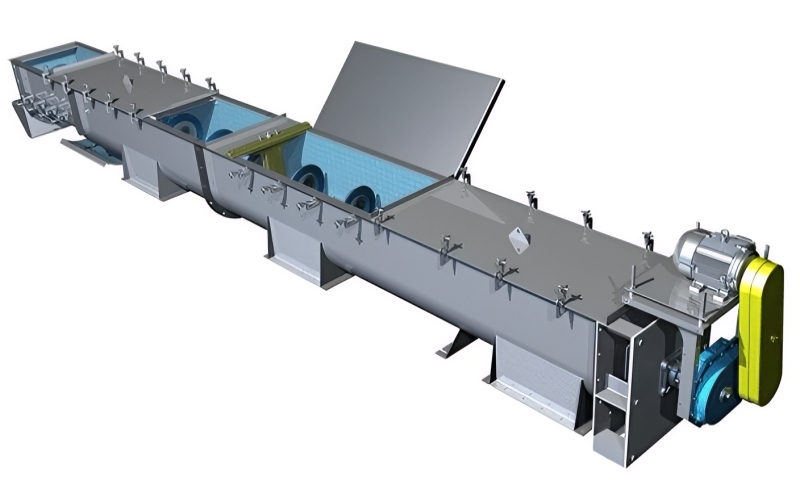

MultiBlast PROBRS12000 Twin Blasting Room Container Blast System with Fully Auto Recovery System

The MultiBlast PROBRS12000 Twin Blasting Room Container Blast System with Fully Auto Recovery System with Recovery System offer a wide range of Abrasive Blast Rooms in a variety of configurations for all types of cleaning, peening and finishing operations. MultiBlast PROBRS also recognize the need for Blast Cleaning in remote locations and smaller Blast Operations and thus included into the range the Container Blast Room. A purpose built, easily relocatable system comprises all the features of the larger MultiBlast Blast Rooms.

#BBD0E0

»

MultiBlast PROBRS12000 Twin Blasting Room Container Blast System with Fully Auto Recovery System

MultiBlast PROBRS12000 Twin Blasting Room Container Blast System with Fully Auto Recovery System

Description

The MultiBlast PROBRS12000 Twin Blasting Room Container Blast System with Fully Auto Recovery System with Recovery System offer a wide range of Abrasive Blast Rooms in a variety of configurations for all types of cleaning, peening and finishing operations. MultiBlast PROBRS also recognize the need for Blast Cleaning in remote locations and smaller Blast Operations and thus included into the range the Container Blast Room. A purpose built, easily relocatable system comprises all the features of the larger MultiBlast Blast Rooms.

Inclusions

- 1 x Blasting Room Body: 2 x 40FT container, wear resistant rubber guard plate, etc.

- 1 x Sand blasting machine: 3m3 blasting pot, level gauge, 10m (1pc) blasting hose fast coupling connector, 1 x of blasting gun with Φ10 Venturi nozzle

- 1 x Floor Recovery System: Crosswise screw conveyor with shaft, Mn16 screw blades, scraper, cylinder, grating floor and housing

- 1 x Bucket Elevator: Including housing, hood shield, middle shield, bottom shield, reduction box, elevator belt, buckets,

- 1 x Abrasive Separator: Including separation area, hopper duct, fine abrasive storage hopper etc.

- 16 x Lighting fixtures: Including LED lamp, Explosion-proof organic glass, etc.

- 1 x Abrasive Supply System: Including pneumatic gate valve, slide pipe, cylinder, etc.

- 1 x Dust Collector: Including pressure centrifugal fan, cartridge filters, ducts, maintenance platform etc.

- 1 x Electric control system: Dust proof electric cabinet, failure warning, low voltage apparatus, etc.

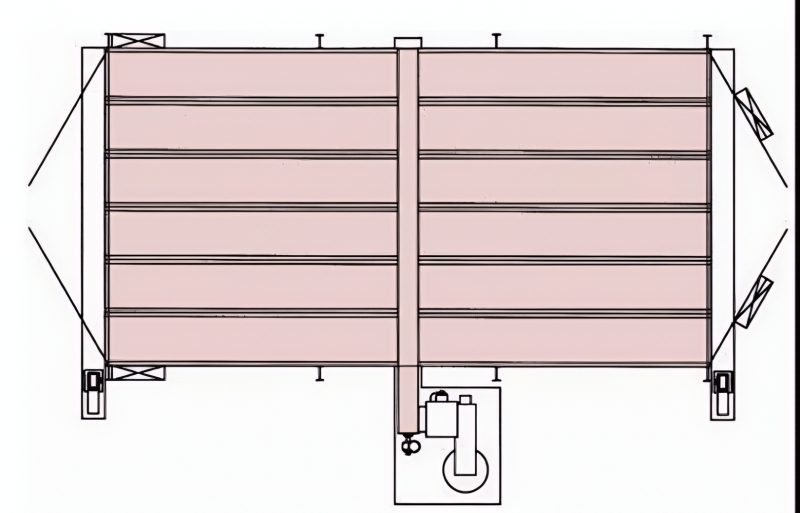

Blasting Chamber

- The blast room is constructed from two 40- foot shipping containers, providing a durable, modular solution for surface preparation tasks.

- The interior walls are lined with heavy- duty, abrasion-resistant rubber These liners are designed to withstand continuous operation—up to 8 hours a day, 6 days a week—with an expected service life of over 7 years.

- In addition to superior wear resistance, the rubber lining also offers sound-dampening properties, reducing noise levels within the chamber for a safer and more comfortable working environment.

Blasting Pot and Nozzle System

- The system is equipped with a high- capacity 500L blast pot, designed to operate continuously for up to 2 hours without the need for abrasive refilling. Each blast pot is hydrostatically tested and certified to operate at 8 Bar, in compliance with GB 1–150.4-2011 standards, and comes with individual product coding and certification.

- The blasting system features an advanced Venturi-style blast nozzle, combining a lightweight aluminium and polyurethane construction. This design offers excellent balance, durability, and shock absorption, outperforming traditional metal-cased

- The long Venturi design is engineered to maximise abrasive velocity and coverage, increasing productivity and delivering enhanced abrasive impact—especially effective on tough or heavily contaminated surfaces.

Bucket Elevator System

- The elevator system features a flat belt drive with wear-resistant hopper lips, ensuring durability in abrasive environments. The elevator casing is modular and sectioned, allowing for easy disassembly during servicing. It also includes inspection and maintenance windows for convenient access.

- A belt tensioning device is installed at the top of the hoist, enabling simple and precise adjustment of belt tightness to maintain optimal performance.

- The bucket elevator is fitted with an anti- reverse mechanism, which prevents reverse movement in the event of a power failure or unexpected stoppage.

- For enhanced safety and reliability, the system includes a belt fault sensor and alarm, which triggers an interlock shutdown and alerts operators in the event of a malfunction.

Separator

- The system utilises a state-of-the-art curtain-type air wash separator, delivering superior abrasive purification. This advanced design achieves a dust content of less than 6% in the cleaned steel shot, ensuring consistent blasting quality and extended media life.

- Steel shot delivered by the bucket elevator is evenly distributed via a screw conveyor, forming a “waterfall” curtain of abrasive as it enters the separator.

- Using the gravity winnowing principle, the system effectively separates reusable steel shot from metal oxide scale, broken particles, and dust—resulting in cleaner, more efficient blasting.

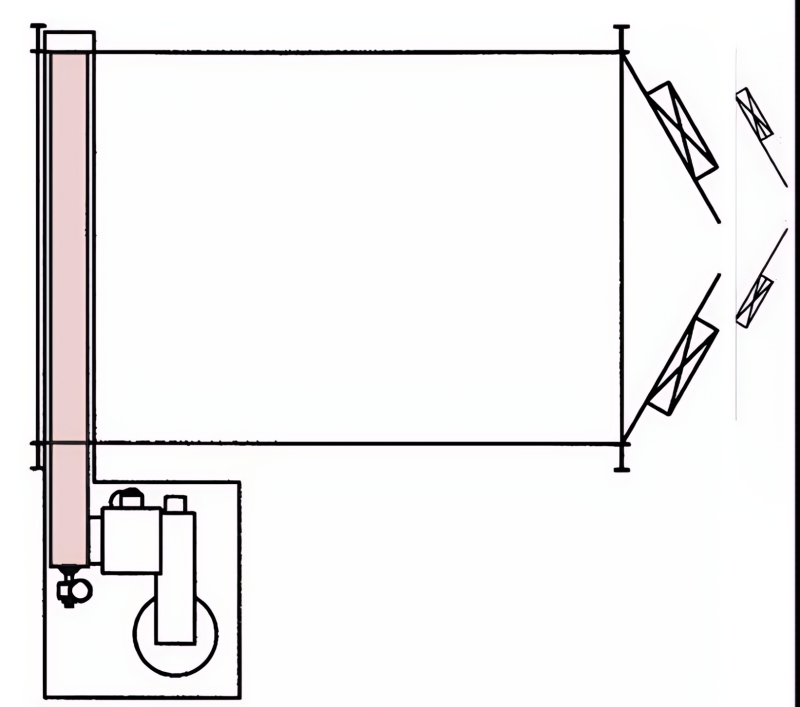

Unique Sweeper Blade Full Floor Reclaim System

This advanced recovery system offers significant installation cost savings, as it requires only a shallow concrete foundation. This design is ideal for sites where high water table levels make deep excavations problematic.

The full floor reclaim setup is fully integrated into the blast room layout and must be carefully considered alongside material handling requirements. Options include:

- Work car and track system

- Overhead monorail or bridge crane

- Guide rail work cars

Heavy-duty floor grating and reinforced support steel, capable of supporting forklift traffic

This system is highly adaptable and can be incorporated into any blast room configuration, making it the preferred solution for high- production environments that require efficient media recovery and robust material handling.

Single Scraper Partial Reclaim System

This is the most cost-effective floor recovery option, ideal for low to medium production levels.

The system includes:

- Scraper or screw conveyor

- Heavy-duty screw belt and bucket elevator

- Air-wash separator

- Perforated plate rotary drum separator

- Oversized abrasive storage hopper with caged access ladder and handrail

While economical, this system is also modular and expandable, allowing upgrades to an “H”, “U”, or full floor reclaim system as production demands increase. It provides a reliable and scalable solution for operations requiring basic yet effective abrasive recovery.

Screw Conveyor System

- The screw conveyor is a key component of the abrasive recovery system, responsible for the horizontal transport of steel shot. It consists of a cycloidal reducer, screw shaft, protective cover, belt bearings, and related components.

- This equipment is designed as a standardised, modular unit, offering high interchangeability, stable performance, and easy The entire screw shaft is precision-machined after welding to ensure perfect coaxial alignment, contributing to smooth and reliable operation.

- The screw blades are made from Mn16 high-manganese steel, processed using a specialised technique to achieve high dimensional accuracy in both pitch and diameter. This results in a longer service life and enhanced wear resistance, even under continuous operation.

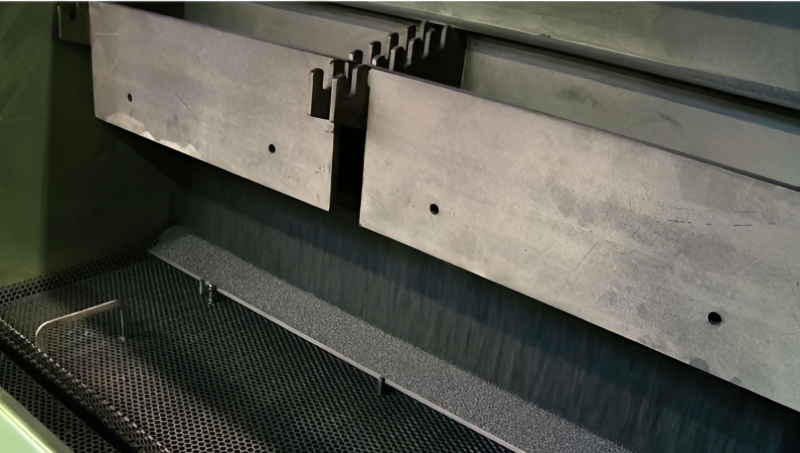

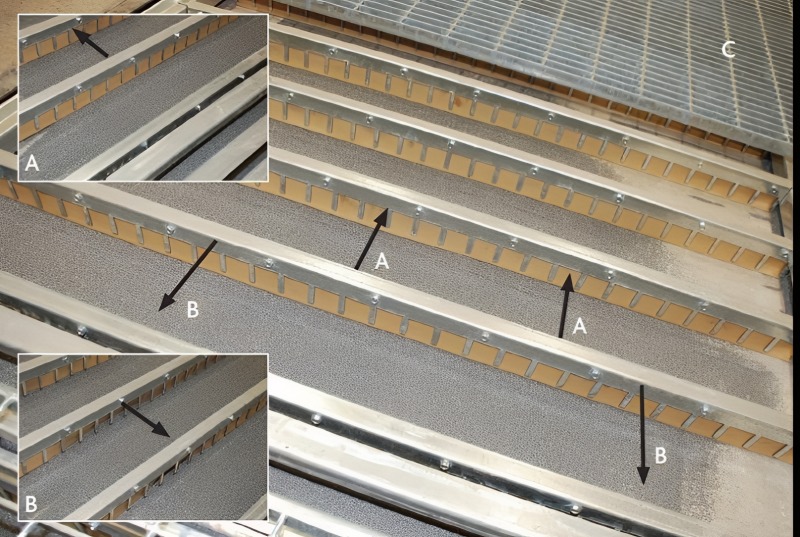

Scraper Recovery System

The scraper recovery system efficiently moves spent abrasive along the floor for recycling, using a smart push-and-return mechanism.

- The scrapers are spaced closer than their stroke distance, allowing each scraper to push abrasive forward during the forward stroke. This is achieved as the rubber flap locks against a steel comb, creating a shunting motion (A).

- On the return stroke, the rubber blade flexes over the abrasive previously deposited, without disturbing it (B).

- The abrasive is steadily advanced to a crosswise screw conveyor, which transfers it to the bucket elevator for recovery and reuse

- The entire system is covered with heavy- duty pedestrian floor grating (C), allowing operators to walk safely above while spent abrasive falls through the grating to the scraper system below.

This design ensures continuous abrasive recovery with minimal operator intervention and safe, ergonomic access within the blasting area.

Dustproof LED Lighting

- The blast room is equipped with high- efficiency dustproof LED light fixtures, designed to provide maximum illumination and ensure clear visibility during

- Each fixture features a quick-release fastening system, allowing for easy removal and maintenance without the need for specialised tools

These LED lights are energy-efficient, low- maintenance, and well-suited for the harsh environment of abrasive blasting applications.

Cartridge Filter Dust Collector

- The dust collection system is a two-stage design, comprising a settling chamber followed by high-efficiency cartridge This setup delivers a cleaning efficiency of up to 99.5%, ensuring a safe and dust-free working environment.

- Premium filter material sourced from Donaldson is used, with each cartridge offering an effective filtration area of up to 15 m².

- An integrated air shock valve with a timing device automatically cleans the filters at regular intervals, maintaining consistent

- The system is low-maintenance and cost- effective, requiring only periodic cartridge

- Filter replacement is fast, simple, and clean – performed from outside the unit without tools or entry into confined This not only improves safety but also reduces downtime.

This makes the cartridge dust collector an ideal, economical solution for high-performance dust control in blasting operations.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

MultiBlast PROBRS12000 Twin Blasting Room Container Blast System with Fully Auto Recovery System

Technical Specifications

| ITEMS | QTY | PARAMETERS | SPECIFICATION |

|---|---|---|---|

| MultiBlast PROBRS Blasting Room Container Blast System | |||

| Cleaning Effect | The degree of surface | ISO 8501-1 – Sa 2.5 | |

| Class of surface | ISO 8501-1 – average | ||

| Surface roughness | ISO 8501-1:1988 40μm~80μm | ||

| Abrasive Specification | Diameter | φ0.8~φ1.5 mm | |

| Initial filling capacity | 1t | ||

| Blasting Room | |||

| Blasting Room | 1 | Type | 2*40FT Container |

| External size | 12.19m4.86m2.59m | ||

| Inner size | 12m4.7m2.385m | ||

| Protect Plate Material | Anti-Abrasive Rubber | ||

| Protect Plate Thickness | 5mm | ||

| Sandblasting Machine | |||

| Sandblasting Machine | 1 | Shot Gun quantity | 2 pcs (pneumatic remote control) |

| Nozzle material | boron carbide | ||

| Venturi nozzle diameter | Φ10 mm | ||

| Working air pressure | 5-8bars | ||

| Volume of in-tank | 0.5m3 | ||

| Emitted dose | 3800kg/h | ||

| Abrasive initial filling capacity | 0.5 tons | ||

| Air Consumption | 2*6m3/min | ||

| Bucket Elevator | |||

| Bucket Elevator | 1 | Lifting capacity | 15t/h |

| Power | 3kw | ||

| Speed | 1.6m/s | ||

| Floor Recovery System | |||

| Full Automatic Floor Recovery System | |||

| Full Automatic Floor Recovery System | 4 | Longitudinal Scraper Recovery System | Direction: Longitudinal |

| Length: 12m | |||

| Control: Pneumatic control (cylinder) | |||

| 1 | Crosswise screw conveyor | Direction: crosswise | |

| Length: 5m | |||

| Power: 3kw | |||

| Abrasive Separator | |||

| Abrasive Separator | 1 | Power | Share the same with bucket elevator |

| Separation capacity | 15t/h | ||

| Type | Multiple air wash type | ||

| Air speed | 4-5m/s | ||

| Dosing unit | abrasive dosing unit (manual+air cylinder control) | ||

| Dustproof LED Lamp | |||

| Dustproof LED Lamp | 16 | Illumination | More than 200lm/w |

| Power | 150w | ||

| Total power | 2.4kw | ||

| Ventilation Capacity | |||

| Ventilation capacity | Required ventilation capacity of the blasting room | 19440 m3/h | |

| Ventilation speed | 0.1m/s | ||

| Dust collector (Donaldson filter material, Sequence timer for cleaning of filtering elements) | |||

| Dust collector | 1 | Type | HL-24 |

| Quantity of cartridge filters | 24 pieces | ||

| Fan Power | 18.5kw | ||

| Dust collecting efficiency | ≥99.5% (automatic pulse jet blowback cartridge filter cleaning) | ||

| Filtering area | about 360 square meters | ||

| Exhaust emissions | <80 mg/ m3 | ||

| Collection Silos | 1 | Storage capacity | 1t |

| Ladders with Maintenance Platform | 1 | Features | Platform and ladder with protection, manhole for servicing |

| Entire machine noise | ≤85dB | ||

| Electric Control System | 1 | Components | Schneider electric components |

| Total power | 26.9kw | ||

Frequently Asked Questions

What type of warranty and after-sales support do you provide with these machines or products ?

- Spare Parts Availability: We keep a wide range of commonly used spare parts and consumables in stock.

- Pre-Dispatch Checks: All machinery is thoroughly checked and pre-commissioned before leaving our facility.

- Support Options in the Event of a Fault:

- Remote Support: Assistance via email, phone, or live video to help diagnose and resolve issues.

- On-Site Service: Repairs carried out by our in-house service engineers or trusted repair contractors.

- In-House Repairs: Machines can be returned to us for expert inspection and servicing.