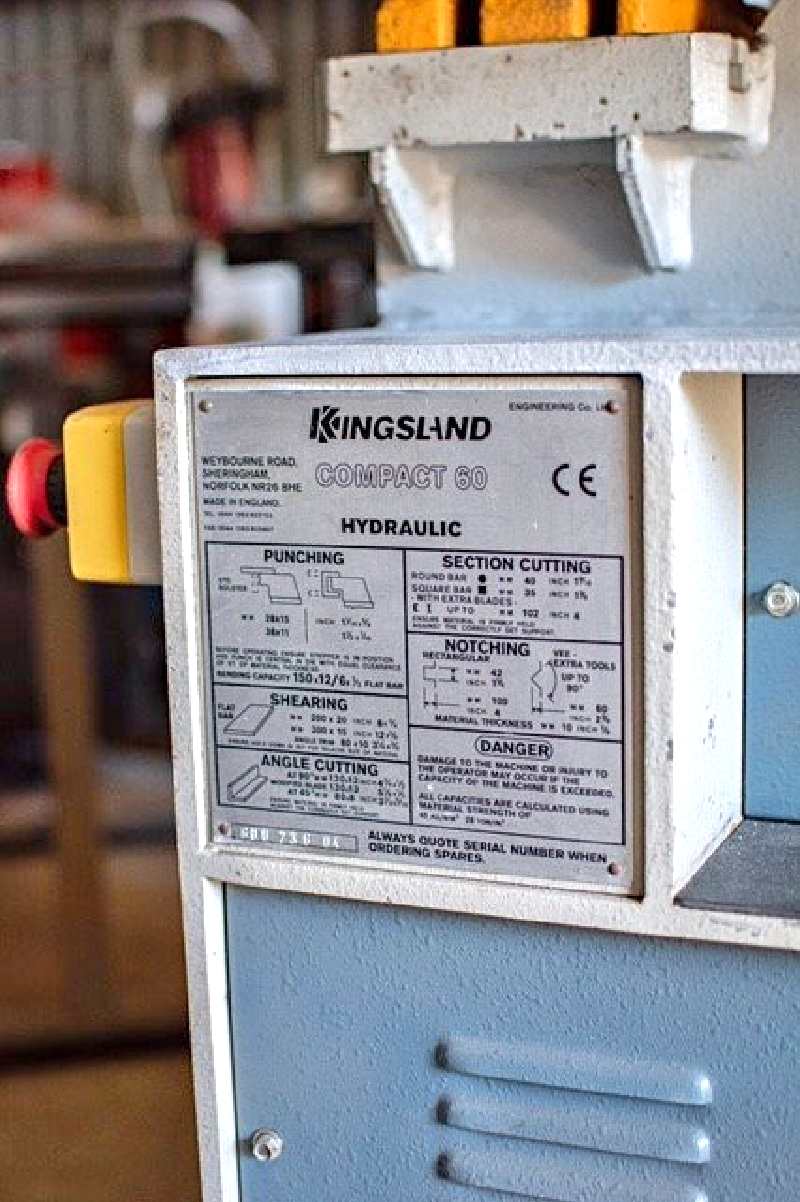

Used Kingsand Compact 60 Punch And Shear

- Brand: Kingsland

Out of stock

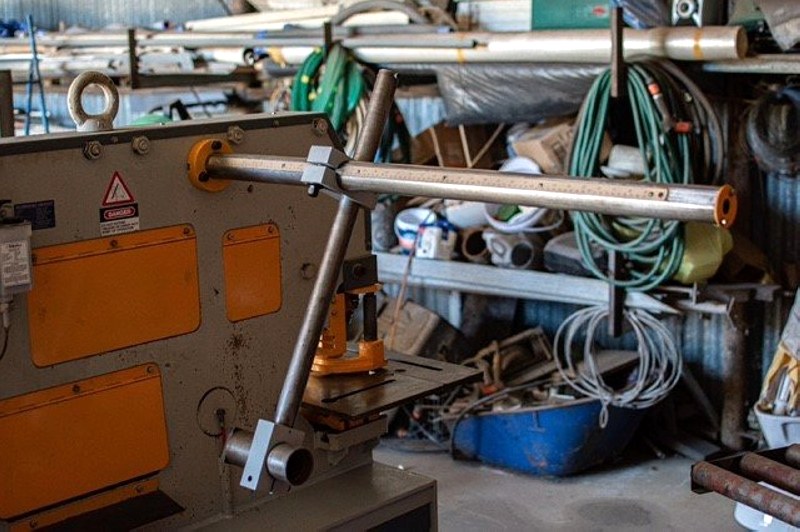

The Compact 60 Punch and Shears are universal and compact hydraulic steelworkers with 5 workstations, developed for production purposes with maximum efficiency. The Compact machines are designed and manufactured using our long experience in manufacturing of hydraulic steelworkers.

Used Kingsand Compact 60 Punch And Shear

Used Kingsand Compact 60 Punch And Shear

Description

![]() Kingsland Compact 60 Hydraulic IronWorker Manual

Kingsland Compact 60 Hydraulic IronWorker Manual

The Compact 60 Punch and Shears are universal and compact hydraulic steelworkers with 5 workstations, developed for production purposes with maximum efficiency. The Compact machines are designed and manufactured using our long experience in manufacturing of hydraulic steelworkers.

Shielded foot control

The hydraulic circuit is activated by a shielded foot-pedal. The inch mode on each workstation enables the correct work piece positioning and tool alignment. Limit switches allow accurate adjustment of the stroke length for maximum efficiency. Stroke with automatic return.

Angle cutting

On the angle cutting station, angle iron can be cut on every angle from 45° up to 90°, both internal and external, without any adaptations to the machine. Flanges from larger angle iron can be mitre cut with the shear.

Low maintenance

Moreover, the machines are equipped with centralised pressure lubrication – being one feature of the low maintenance requirements

5 Workstations and an extensive range of standard equipment

The universal steelworkers are delivered with an extensive range of standard equipment, such as large heavy-duty tables on the punch-, shear-, and notching station. Easy adjustable hold-downs to enable production in a safe and accurate way are fitted on every station. Free standing on suitable floor, they just need electrical connection to be ready to work.

- Punch station – The easy tool change system and swing-away stripper with fast manual adjustment assures a quick setup and is designed for a wide range of punching applications.

- Section cutting station – The machines are fitted as standard with blades for cutting round and square bars. With extra equipment in this aperture, the machines are able to cut channel, beams or joist, T-section and many other special profiles.

- Angle station – Cropping angle iron is possible for every angle between 45° and 90°, both internal and external.

- Shearing – Specially designed blade approach angle to avoid the necessity to change blade settings when cutting thick or thin material and yet offer minimum distortion cropping.

- Notching station – This versatile unit is standard equipped with a rectangular notch unit. The notch table has adjustable back and side stops. Side notch applications are also possible.

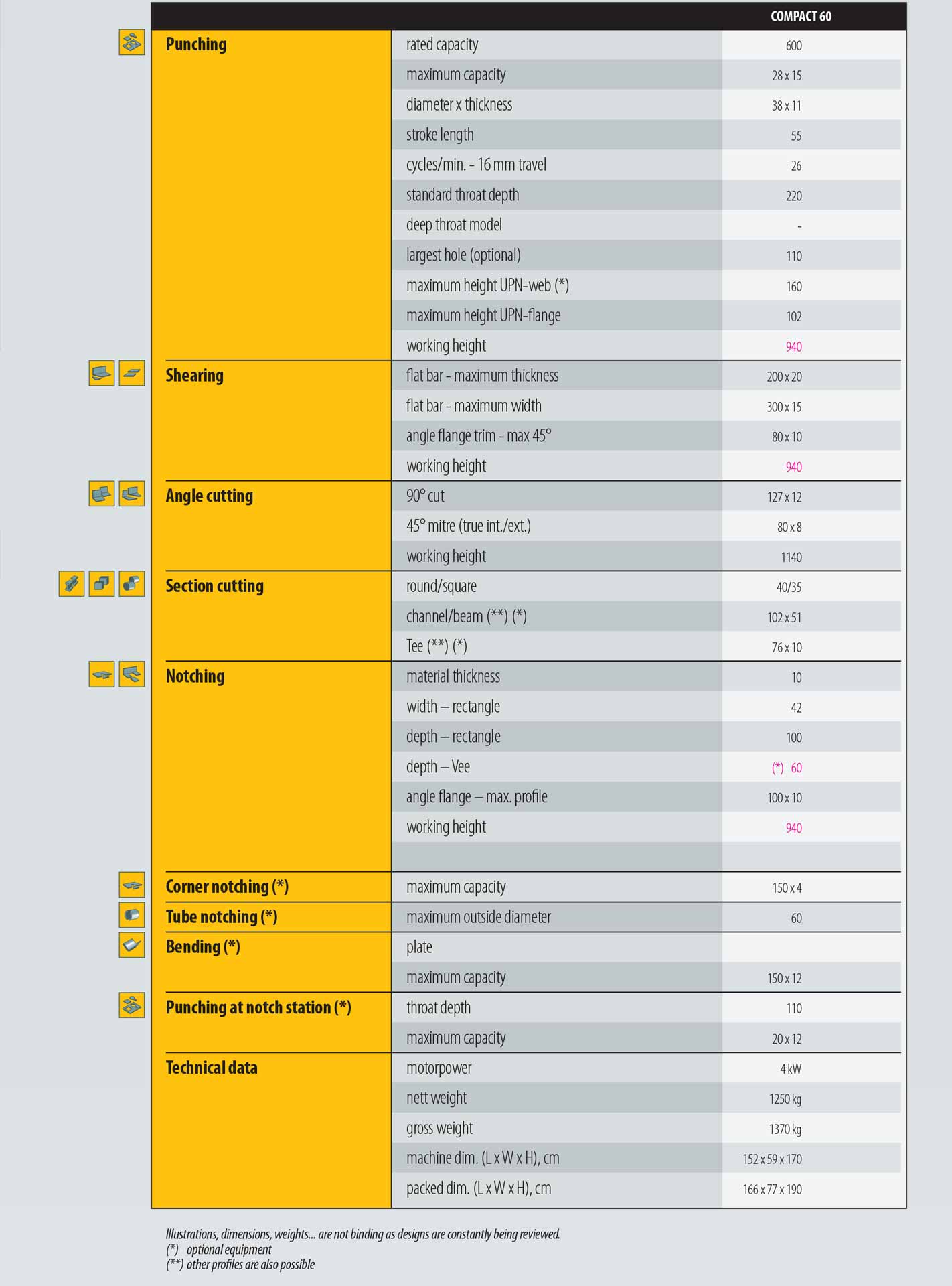

Model Specification

| Workstations | Description | COMPACT 60 |

| Punching |

rated capacity

|

600 |

| maximum capacity | 28 x 15 | |

| diameter x thickness | 38 x 11 | |

| stroke length | 55 | |

|

cycles/min. – 16 mm travel

|

26 | |

|

standard throat depth

|

220 | |

|

deep throat model

|

– | |

|

largest hole (optional)

|

110 | |

|

maximum height UPN-web (*)

|

160 | |

|

maximum height UPN-flange

|

102 | |

|

working height

|

940 | |

| Shearing | flat bar – maximum thickness flat bar – maximum width angle flange trim – max 45° working height | 200 x 20 300 x 15 80 x 10 940 |

| Angle cutting | 90° cut 45° mitre (true int./ext.) | 127 x 12 80 x 8 |

| working height | 1140 | |

| Section cutting | round/square channel/beam (**) (*) Tee (**) (*) | 40/35 102 x 51 76 x 10 |

| Notching |

material thickness

|

10 |

|

width – rectangle

|

42 | |

|

depth – rectangle

|

100 | |

| depth – Vee | (*)60 | |

| angle flange – max. profile | 100 x 10 | |

|

working height

|

940 | |

| Corner notching (*) | maximum capacity | 150 x 4 |

| Tube notching (*) |

maximum outside diameter

|

60 |

| Bending (*) | plate maximum capacity | 150 x 12 |

| Punching at notch station (*) | throat depth maximum capacity | 110 20 x 12 |

| Technical data | motorpower | 4 kW |

| nett weight | 1250 kg | |

| gross weight | 1370 kg | |

| machine dim. (L x W x H), cm | 152 x 59 x 170 | |

| packed dim. (L x W x H), cm | 166 x 77 x 190 |

Illustrations, dimensions, weights… are not binding as designs are constantly being reviewed. (*) optional equipment (**) other profiles are also possible

Frequently Asked Questions

What type of warranty and after-sales support do you provide with these machines or products ?

- Spare Parts Availability: We keep a wide range of commonly used spare parts and consumables in stock.

- Pre-Dispatch Checks: All machinery is thoroughly checked and pre-commissioned before leaving our facility.

- Support Options in the Event of a Fault:

- Remote Support: Assistance via email, phone, or live video to help diagnose and resolve issues.

- On-Site Service: Repairs carried out by our in-house service engineers or trusted repair contractors.

- In-House Repairs: Machines can be returned to us for expert inspection and servicing.

Specification

Additional information

| Weight | 1370 kg |

|---|---|

| Dimensions | 166 × 77 × 190 cm |

| Kilowatt (kW) |