-

LivMakina LVH 32 CNC Mandrel Tube Bending Machine

The LivMakina LVH 32 CNC Mandrel Tube Bending Machine should be preferred in order to prevent problems such as ovalization, cracking, and breaking during bending. CNC machines are an ideal option for thin walled pipes. With the integration of the latest technology into the machines, a quality in European standards emerges. Thanks to the 3D simulation feature on CNC machines, it is possible to carry out the design before starting the operation. All practical features such as storing products in memory, multiple language options, touch screen, PLC control system, error detection system, automatic pipe length calculation are included in CNC pipe machine models.

Product ID: LVH-32-CNC -

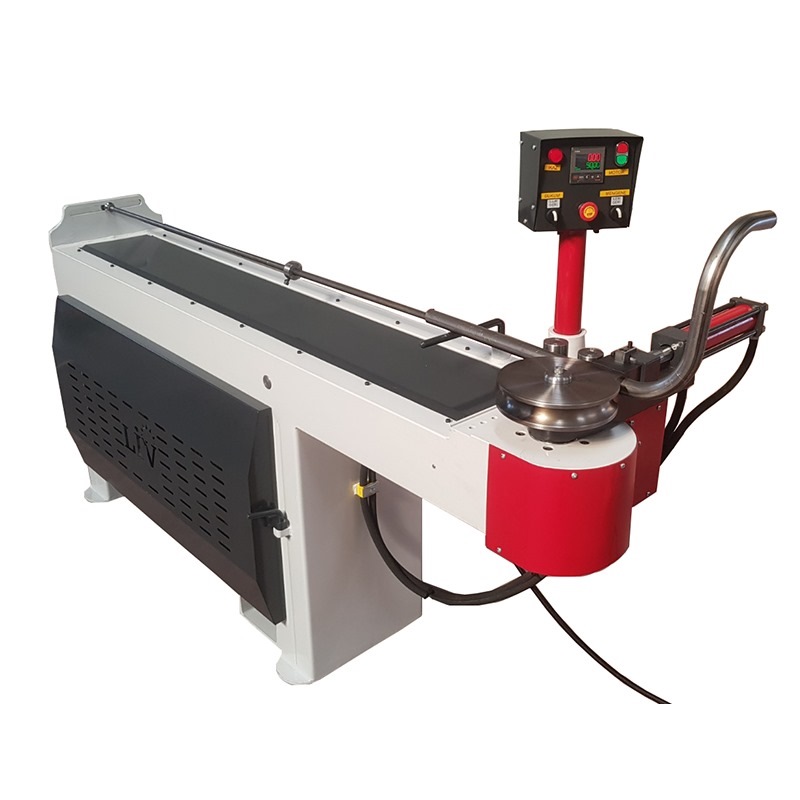

LivMakina LVH 32 NC Semi Automatic Mandrel Tube Bending Machine

The LivMakina LVH 32 NC Semi Automatic Hydraulic Mandrel Pipe Bending Machine is a 40-liter hydraulic oil tank with 4HP electric power, which can bend pipes and profiles of various sizes and thicknesses up to 32 mm in diameter and in accordance with the desired diameter / mold dimensions, with the digital display at the desired angles. It is a pipe bending machine without reducer that performs circular movement by transferring the linear motion of the hydraulic piston connected to the other rack to the gear after clamping the pipe with the force it makes to the hydraulic piston mounted on the pipe bending machine with the pump pressure connected to the motor.

Product ID: LVH-32-NC-SEMI -

LivMakina LVH 38 DH Mandrel Tube Bending Machine

The LivMakina LVH 38 DH Mandrel Tube Bending Machine are state-of-the-art machines that can perform two bends simultaneously. The ability to bend more than one pipe at a time creates a great advantage. It is possible to make angle adjustments at the same angle or at two different angles. Such machines are used in sectors serving automotive industry, furniture and hardware.

Product ID: LVH-38-DH -

LivMakina LVH 38 DHX Mandrel Tube Bending Machine

The LivMakina LVH 38 DHX Mandrel Tube Bending Machine are state-of-the-art machines that can perform two bends simultaneously. The ability to bend more than one pipe at a time creates a great advantage. It is possible to make angle adjustments at the same angle or at two different angles. Such machines are used in sectors serving automotive industry, furniture and hardware.

Product ID: LVH-32-DHX -

LivMakina LVH 42 CNC R3 Mandrel Tube Bending Machine

The LivMakina LVH 42 CNC R3 Mandrel Tube Bending Machine should be preferred in order to prevent problems such as ovalization, cracking, and breaking during bending. CNC machines are an ideal option for thin walled pipes. With the integration of the latest technology into the machines, a quality in European standards emerges. Thanks to the 3D simulation feature on CNC machines, it is possible to carry out the design before starting the operation. All practical features such as storing products in memory, multiple language options, touch screen, PLC control system, error detection system, automatic pipe length calculation are included in CNC pipe machine models.

Product ID: LVH-42-CNC -

LivMakina LVH 51 CNC Mandrel Tube Bending Machine

The LivMakina LVH 51 CNC Mandrel Tube Bending Machine should be preferred in order to prevent problems such as ovalization, cracking, and breaking during bending. CNC machines are an ideal option for thin walled pipes. With the integration of the latest technology into the machines, a quality in European standards emerges. Thanks to the 3D simulation feature on CNC machines, it is possible to carry out the design before starting the operation. All practical features such as storing products in memory, multiple language options, touch screen, PLC control system, error detection system, automatic pipe length calculation are included in CNC pipe machine models.

Product ID: LVH-51-CNC -

LivMakina LVH 51 NC Semi Automatic Mandrel Tube Bending Machine

The LivMakina LVH 51 NC Semi Automatic Mandrel Tube Bending Machine have become the most modern thanks to the systematic integration of technological innovations into the machines. Semi-automatic pipe bending machines are preferred in order to avoid the frequently encountered problems in manual processes. It is ideal for sectors that need more limited capacity bending. The features in its design help the pipe to be bent in the desired geometry. The need for pipes in furniture production such as tables and chairs can be met with these machines.

Product ID: LVH-51-NC-SEMI -

LivMakina LVH 51 SEMI CNC Mandrel Tube Bending Machine

The Pipes may differ according to the raw material they are produced from and their size characteristics. These differences are taken into account in forming processes. A suitable pipe bending machine will be needed to make the desired bending. LivMakina LVH 51 SEMI CNC Mandrel Tube Bending Machine come into play at this point. Bending technology, which ensures high quality standards, successfully carries out all operations that require precision. Desired results can be achieved in a short time with our LivMakina LVH 51 SEMI Mandrel CNC Tube Bending Machine, which are a reflection of our experience in this field. All the features required for an error-free, problem-free and highly efficient pipe bending process are available in our CNC machines.

Product ID: LVH-51-SEMI-CNC -

LivMakina LVH 65 CNC Mandrel Tube Bending Machine

The LivMakina LVH 65 CNC Mandrel Tube Bending Machine should be preferred in order to prevent problems such as ovalization, cracking, and breaking during bending. CNC machines are an ideal option for thin walled pipes. With the integration of the latest technology into the machines, a quality in European standards emerges. Thanks to the 3D simulation feature on CNC machines, it is possible to carry out the design before starting the operation. All practical features such as storing products in memory, multiple language options, touch screen, PLC control system, error detection system, automatic pipe length calculation are included in CNC pipe machine models.

Product ID: LVH-65-CNC -

LivMakina LVH 65 NC Semi Automatic Mandrel Tube Bending Machine

The LivMakina LVH 65 NC Semi Automatic Mandrel Tube Bending Machine have become the most modern thanks to the systematic integration of technological innovations into the machines. Semi-automatic pipe bending machines are preferred in order to avoid the frequently encountered problems in manual processes. It is ideal for sectors that need more limited capacity bending. The features in its design help the pipe to be bent in the desired geometry. The need for pipes in furniture production such as tables and chairs can be met with these machines.

Product ID: LVH-65-NC-SEMI -

LivMakina LVH 65 SEMI CNC Mandrel Tube Bending Machine

The Pipes may differ according to the raw material they are produced from and their size characteristics. These differences are taken into account in forming processes. A suitable pipe bending machine will be needed to make the desired bending. LivMakina LVH 65 SEMI CNC Mandrel Tube Bending Machine come into play at this point. Bending technology, which ensures high quality standards, successfully carries out all operations that require precision. Desired results can be achieved in a short time with our LivMakina LVH 65 SEMI CNC Mandrel Tube Bending Machine, which are a reflection of our experience in this field. All the features required for an error-free, problem-free and highly efficient pipe bending process are available in our CNC machines.

Product ID: LVH-65-SEMI-CNC

All Products

- Home

- Air Compressors & Blasting Equipment

- Metal Cutting Saws

- Bandsaw and Cold Saw Blades

- Brobo Machinery

- Tooling & Blades

- Beveling Machines

- Conveyor Systems

- Coolants and Lubricants

- Engineering Machinery

- Forklift

- Hydraulic Tools and Lifting

- Drills Linishers & Belt Grinders

- Pipe and Bar Threaders

- Pipe, Tube & Bar Benders

- Punches and Dies Shear Blades

- Safety and Guarding

- Sheet Metal and Fabrication

- Spare Parts and Accessories

- Used Machinery

- Rebar Machinery

- Punching / Punch And Shears

- Welding Equipment

- Flange Facing Equipment

- Pages

- Request a Quote

- Resources

- Account